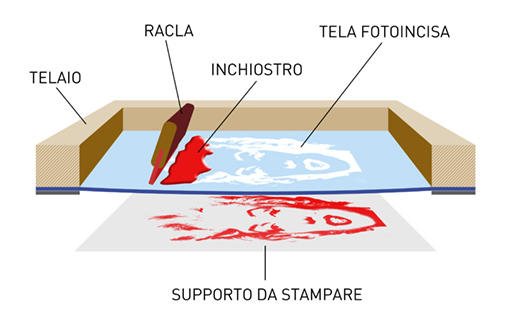

Screen printing

Screen printing is a one or multi-color printing technique that involves the use of a frame. It is used to reproduce images or documents on any material, although, in the promotional world, it is mainly used for the customization of t-shirts or shopping bags. The term derives from the Latin seri (silk) and the Greek γράφειν (gràphein, to write). It is one of the oldest printing techniques. To trace its origins, in fact, we must go back to ancient China and precisely to the Song Dynasty (960-1279 AD). It is said that the first looms were made using women's hair, soon replaced by silk, from which the printing technique takes its name. In the Western world, screen printing (or silkscreen printing) became famous and popular thanks to billboards, but also and above all for the use made by world-famous artists such as Andy Warhol, who often used it to create his works.

Pad printing

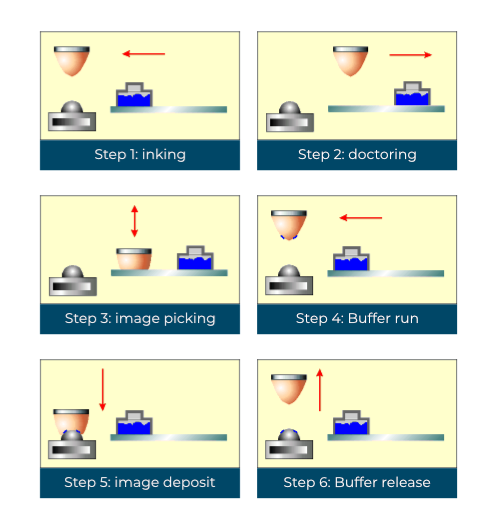

The theory of the pad printing method has actually taken over many aspects of screen and gravure printing, combining them in a completely new way. Initially there were copper plates on which images were engraved, with a method very similar to the process of photoengraving. Since then the methods and materials have changed, but the end result is still a plate containing an engraved image. The surface of the plate is inked and then wiped clean in much the same way that, in the field of screen printing, a frame is inked and then squeegeed. But in pad printing, this does not involve the immediate transfer of the image. It involves a pad being pressed against the plate first, so that the image is picked up, and then immediately transferred to the surface of the object. The procedure may appear similar to that of rotogravure printing, but it differs in that in our case the pad is not the source of the image, but the means of transferring it. All pad printing machines are based on two basic operating systems, commonly called "open" and "closed".

The image to be transferred is engraved on a special plate, called a cliché. Once the plate is installed in the printing press, its surface is inked, then doctored so that the ink remains only in the area of the image to be reproduced. In particular, the ink is not directly exposed to the air, but rather placed in an "airtight" container, called a "glass". Inking takes place while the beaker is positioned above the engraved area. The sharp edge of the tumbler, called the doctoring ring, acts in the same way as the doctor blade in the previous system. In the case of some systems, doctoring occurs when the cup slides along the surface of the plate, in others the cup is fixed and it is the plate that moves below the doctoring ring. Due to the physical alterations undergone during inking (and doctoring) the ink tends to leave the inked area to transfer onto the pad. Once the pad has been lifted from the plate, a short period of time elapses before the ink deposited on it is transferred to the final surface. During this phase the ink undergoes physical changes due to the solvent which, as it evaporates from the outer layer, increases its viscosity. The physical alterations undergone by the ink layer during the printing pass cause it to tend to leave the pad when it is pressed onto the surface to transfer the image. Although the pad compresses considerably during this step, its shape is designed so that it rolls over the final surface instead of pressing flat against it. In fact, a correct pad should not form a 0° angle when in contact with the final surface, as this would cause an air bubble between the pad and the surface, and the risk of the image being reproduced incompletely. Once removed from the surface, the pad will resume its original shape. Provided all variables in the five steps are kept under control, it should be clean and ready for the next cycle.

Digital Printing

The evolution of screen printing and pad printing has led to the introduction of digital printing.

Thanks to this new technology born from an evolution of the normal Jet printers installed in every Italian home. EPS digital inkjet flatbed printing machines allow to print directly on the pieces at high resolution (up to 1200 dpi) in a simple and fast way, transferring the concept of decoration to the industrial level.

They use piezoelectric drop-on-demand heads and UV inks that dry instantly to print in four-color plus two white, primer available on request.

The presence of 2 UV lamps makes it possible to print in bi-directional mode, to the advantage of speed, incredibly lowering production times without sacrificing quality. The RIP software allows the loading of files and the control of all operations, including variable data printing. One of the many advantages is the absence of set-up times, in fact, job changes are quick and clean.

It is possible to customize the machines with handling and vision systems. Ideal for printing on promotional items, prizes, cards, mobile phone covers, stationery, but also for industrial printing in the automotive, medical, cosmetic, tooling, household appliances, etc. sectors.

Hot Foil

Another process with a long tradition is hot foil printing.

The process is used on a wide range of products to create decorative finishes and anti-counterfeiting measures. In the packaging industry, applications include packaging for food, pharmaceuticals, tobacco and luxury goods, as well as labels for products such as wine and spirits. In addition to packaging, hot stamping is widely used on banknotes, greeting cards and all commercial printing and as in our case on plastic components for the household appliance cold sector.

Basically, hot foil stamping is the process of using heat and pressure to apply metal foil or holograms to materials such as lightweight paper, cardboard, laminated board, plastic and corrugated board. Hot ribbon printing allows for beautiful graphic effects using foils that react to pressure and temperature, transferring the mark to the printed material: hence the name. The finish can be metallic, but also pearly and holographic, as well as pastel foils, especially white, to print on colored paper.