Cold Sector

Plenum

The Plenum is a component of the No Frost system. The Total No Frost system eliminates ice from the refrigerator and freezer by blowing cold air into them to reduce humidity. Fridges equipped with the No Frost system are those products with cooling by constant and non-excludable forced air circulation. Thanks to a fan that operates continuously, cold, dry air is introduced into the refrigerator. The uniform circulation of air inside the compartment eliminates humidity, making defrosting unnecessary and keeping food "fresh" longer than in traditional refrigerators. In particular, the Plenum is a component for the cooling system of freezers that is characterized by the presence of a motor that moves the cold air by means of special ducts and a double evaporator that works in the freezer cell independently. It serves to eliminate internal humidity, thus preventing the formation of frost, mold and unpleasant odors related to food. Thanks to the use of the plenum, a high level of food preservation is guaranteed, in particular it allows food labels to remain clearly legible, low level of space usage due to the accumulation of ice, in fact for this reason it is no longer necessary to defrost.

Crisper

The Crisper is a refrigerator component, specifically a white refrigerator drawer. The refrigerator drawers are a practical and functional solution, which allows you to store, fresh, very delicate products such as fruits and vegetables. It allows to ensure inside the refrigerator a division of food so as to allow an excellent preservation of fruits and vegetables.

Heat Sector

Minerva deflector

The deflector represents a device that is able to divert in a certain direction the current of hot air coming from the oven. It is used on pyrolytic ovens. It is produced with the material PPS resistant to high temperatures.

Inner frame Door with gasket

It is an aesthetic component that is specifically assembled to the frame of the inner microwave oven door. The material used for this product is black polycarbonate PBT and pre-assembled with a gasket to adhere to the oven to prevent steam from escaping.

Integrated Handle

Microwave oven door handle produced in PBT raw material, with high aesthetic impact. This component is produced in 3 production steps.

1st step: it is the molding phase for the production of the base material, in particular the plastic part of the component.

2nd step: After the molding phase, the base material is sent to the supplier for the painting phase to make the handle more robust, so as to ensure proper manual use and prevent the concave area from being subject to scratches

3rd step: The last step is the pre-assembly by means of fixing screws of Metal Band (satin aluminum band).

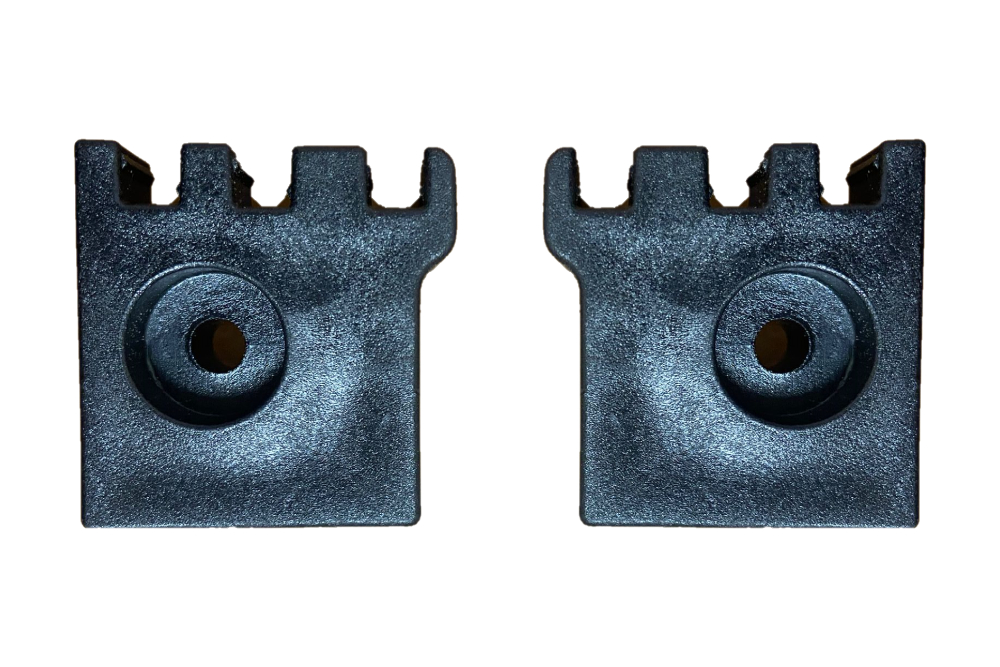

Right and left glass supports

The glass supports are components of the oven. In particular they represent components with low aesthetic impact, produced with PBT material. These components are used on ovens, they are supports for fixing the glass to the oven door, in fact they provide special grooves for the insertion of the glass itself.

Window

It is a highly aesthetic component, mounted on Whirpool high-end ovens. Produced with polycarbonate material, as to guarantee an environmental impact

Washing Sector

Lifter

The Lifter is a functional component of the washing machine. The Lifter guarantees high quality by revolutionizing the washing machine process. The component was introduced to overcome the problems related to washing, especially before the use of Lifter there were problems related to the washing process of the fabrics, which were damaged after the washing phase and not completely clean, often the fabrics were stuck in the basket. Lifters were the solution, as they moved the clothes, allowing the mixture of water and detergent to penetrate into the fabrics evenly, making the stains water-soluble. Thanks to the use of the Lifter, the quality of the performance of the device increased exponentially.

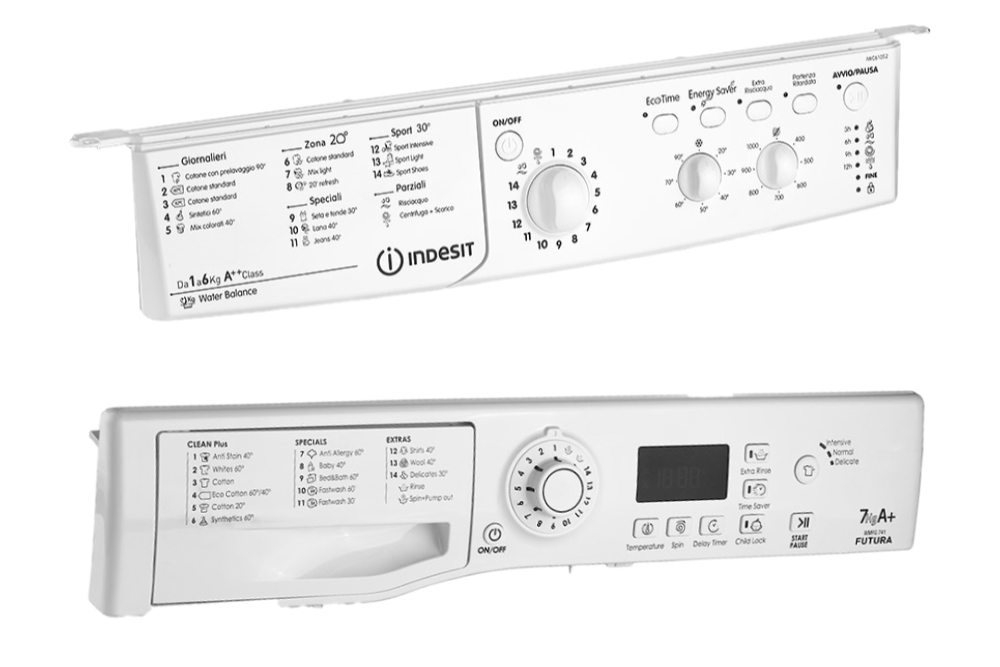

Control panel Ecotime/Futura

The Ecotime or Futura control panel, is a component that performs the function of washing machine control panel, produced in ABS and customized according to customer specifications both in terms of colors and in terms of nationality for the purchasing country. The control panels are composed through different processing phases, in particular, the first phase is characterized by the thermostatic molding of the semi-finished products, dashboard, handle, buttons and light guide. After the molding phase of the basic components, the latter are assembled. Then the pad printing process takes place, which allows the customization of the language for the various programs of use of the washing machine and assembled to an electronic card with preloaded the various washing programs and functions of the washing machine.

Ecoball

Ecoball is a component that belongs to the washing machine discharge circuit, it performs the task of sealing the passage of the detergent from the tank to the discharge pump. The ecoball allows to increase the performance of the washing machine, optimizing the washing process and the use of detergent.

Plastic Disk

The Plastic Disk is a component of the washing machine's drainage system, in particular, being a ring nut, it allows the washing machine's drainage sleeve not to deform and leaves the ecoball inside the sleeve free to work, thus optimizing the process and not creating waste due to the loss of detergent.