Tooling today

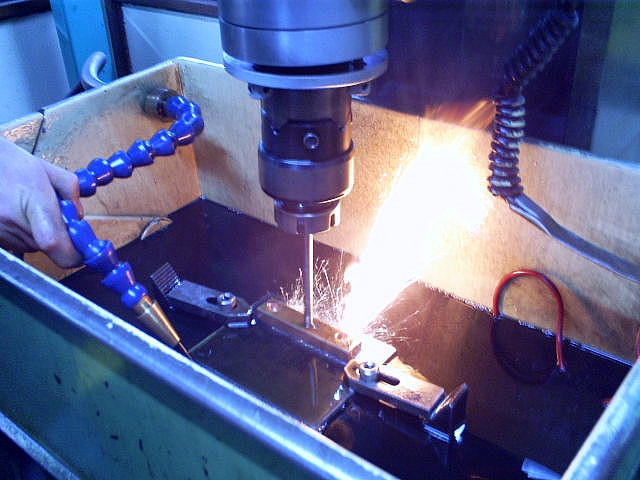

The proliferation of machining centers can give the impression that anyone with the right equipment can build Molds. However, manufacturing and maintaining Molds is still a high-skill activity because you need to have technical knowledge and skills that cover the entire process, including CAD design, selection of materials, machining methods, and performing minute work that cannot be entrusted to automated procedures. In addition, even faster turnaround times are required today because product life cycles are shorter and production includes smaller batches of many items. The emergence of 3D printers is expected to significantly change the way molds are made. Today, further innovations in mold technology are essential. At the disposal of our workshop, in addition to a high level of know-how and many years of experience, there are various equipment including milling machines, lathes, two high-precision numerical centers, and two electric die-sinking machines.