Acroplastica S.r.l is a company operating in the production of plastic components for household appliances. It was founded by entrepreneur Angelo Mastrangelo in 1981 as a spin-off from Whirpool. The founder managed in a short period of time to ensure the achievement of high production and quality targets, leading the company to become a manufacturing excellence in the molding sector in the province of Caserta.

The nineties

Development in Italy

In the 1990s, the management of the company passed into the hands of Mrs. Casuccio, wife of the entrepreneur Mastrangelo who, despite not having any particular experience in the business, immediately showed excellent managerial skills and imposed her own determination and will to preserve the realization of the initial project. Acroplastica established itself as a leading company in the production of plastic components and semi-finished products for the telecommunications, electronics and household appliances sectors, establishing collaborations with major companies in the sector such as Telecom, Siemens and Texas Instruments Incorporated. In 1995 Acroplastica decided to work within the framework of the TQM system, in order to improve the products and services provided to the customer. Acroplastica S.r.l, over the years has focused on improving the management process with quality and innovation. The innovative path has led the company to be certified ISO 9002 in 1997, then underwent an adjustment to UNI EN ISO 9001 in 2003, the certification of the environmental management system, according to UNI EN ISO 14001, in 2000 and subsequent adjustment to the new revision of the standard in 2005, the certification of the social responsibility system, SA 8000, in 1998, a perfect update to the Legislative Decree 626/94 and OHASAS 18001.

2000s Years

Corporate internationalization

At the beginning of the 2000s, the company's production was specialized and focused on the household appliances sector, as telecommunications and electronics companies decided to relocate. During the new millennium the household appliances market has undergone a strong change, due to the suffering of a saturated market and full of competitors who have pushed down both the turnover and the margins on sales. Many competitors have chosen to relocate and open up new markets. In 2012 Acroplastica, in order to ensure a certain competitiveness in the market, undertook an internationalization project by creating a company under Romanian law, the Acroplastica RO, dedicated to the production of plastic components and mouldings for Enel S.p.a. and Technogym S.p.a. After the start-up and consolidation of Acroplastica RO, a difficult period began for Acroplastica Italia since, in addition to the suffering of a saturated market, the main customer Indesit decided at the end of 2013 to close the Teverola plant and move the production lines to Turkey, in particular to the new plant in Turkey in the province of Izmir/Smirne. At the same time, Indesit asked Acroplastica Italia to invest and follow the internationalization project, definitively reinforcing the productive binomial that has linked the two companies for years and creating a privileged partnership. The company's management has succeeded in turning the problem of transferring an entire production facility to Turkey into an opportunity, because while Acroplastica Italia has had a serious impact in terms of a drastic reduction in turnover, the owners have been able to initiate an internationalization process by starting a new company, Acroplastica TK. Acroplastica Italia, regardless of the opportunities seized by the ownership with the internationalization process, found itself facing a downsizing of turnover in 2014 and a further major decline in 2015.

Today

Looking to the future

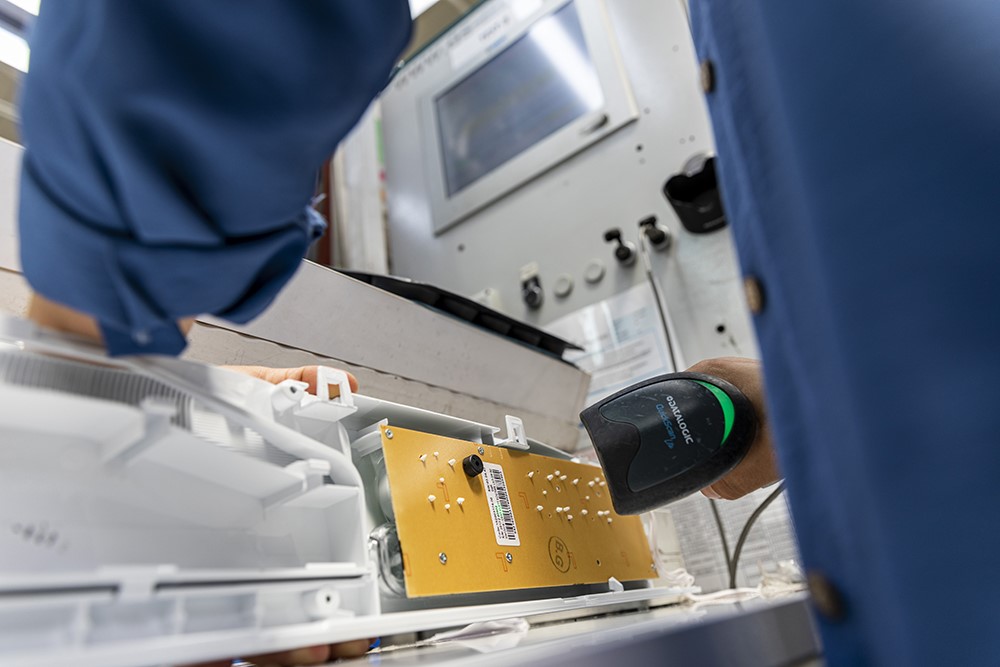

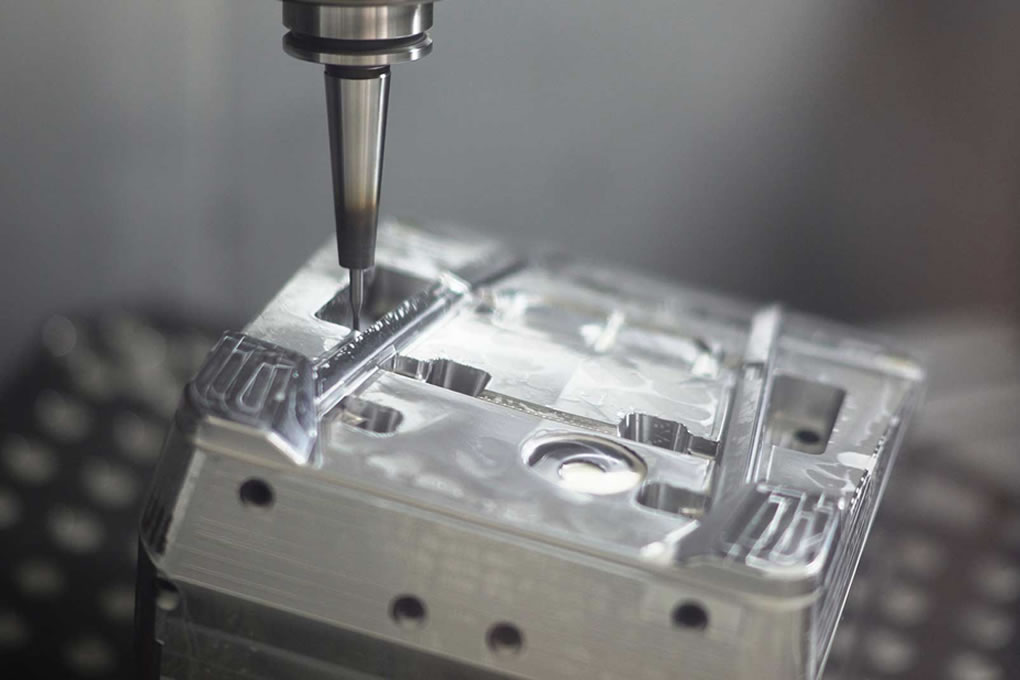

Acroplastica S.r.l. is organized for a precise objective: to be a sure point of reference for those who are looking for a reliable and available partner for the realization of technical components in plastic material. Acroplastica, in fact, is organized for the operation of innovation processes, through an appropriate selection of possible technological changes, using the necessary resources, and of opportunities to improve the relationship with the market and to improve the company's efficiency levels.